Vintage Matchbox cars from the 1950s and 1960s often had diecast metal chassis. This fact shows how Matchbox car design has changed over time. Let’s explore the fascinating world of these miniature vehicles.

Matchbox cars have been beloved toys for generations. They’ve changed from all-metal construction to using mixed materials today. These changes reflect new manufacturing processes and what buyers want.

Understanding Matchbox car design can make you appreciate these miniature marvels more. This guide is for both collectors and casual fans.

We’ll look at how Matchbox chassis design has changed over time. We’ll also explore the use of metal and plastic in today’s models. You’ll learn about the manufacturing processes that create these diecast cars.

Different materials affect how long your toy cars last and how much they’re worth. We’ll help you spot differences in cars made in different regions.

Matchbox cars are more than just toys. They show industrial design skills and reflect car history. For many, they’re treasured items that bring back happy memories.

Key Takeaways

- Vintage Matchbox cars predominantly featured diecast metal chassis

- Modern Matchbox cars utilize a mix of metal and plastic components

- Manufacturing processes have evolved to maintain quality while adapting to new materials

- Understanding chassis materials can help determine a Matchbox car’s value and authenticity

- Regional variations in production can affect the construction and materials used in Matchbox cars

Understanding Matchbox Car Construction and Materials

Matchbox cars have captivated scale model enthusiasts since 1953. These miniature marvels have evolved significantly over the years. They’ve adapted to changing market demands and manufacturing techniques.

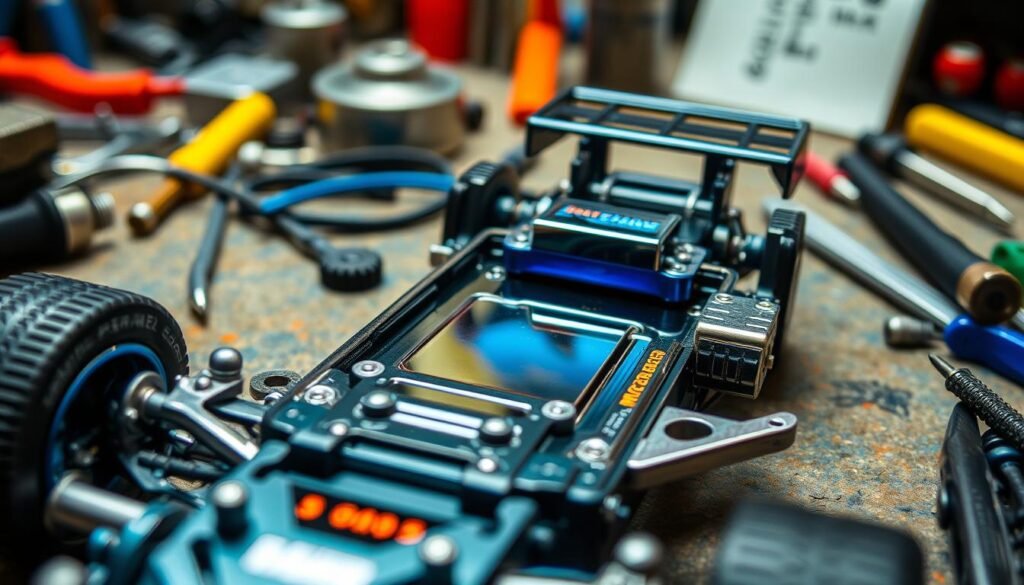

Evolution of Matchbox Chassis Design

Early Matchbox cars featured die-cast construction with metal chassis. In 1968, plastic components were introduced for windows, interiors, and tires.

Competition grew in the late 1960s, prompting Matchbox to innovate. They launched the Superfast line in 1970, featuring faster-rolling wheels.

Metal vs Plastic Components in Modern Matchbox Cars

Today’s Matchbox cars blend metal and plastic elements. The main body often uses die-cast metal. Plastic is common for interiors and details.

This mix offers a balance of durability and detail. Hobby enthusiasts appreciate this combination in their collections.

| Component | Material | Benefit |

|---|---|---|

| Body | Die-cast metal | Durability, weight |

| Chassis | Metal or plastic | Strength, cost-efficiency |

| Windows | Plastic | Clarity, lightweight |

| Tires | Rubber | Realism, grip |

Manufacturing Processes and Quality Control

Matchbox uses die-casting for metal parts and injection molding for plastic. Careful quality control ensures each car meets brand standards.

This attention to detail has kept Matchbox popular. Collectors and casual fans alike appreciate the brand’s commitment to quality.

Matchbox offers over 5000 different die-cast models. These miniature vehicles inspire new generations of collectors. Classic designs and modern replicas provide endless enjoyment for scale model fans.

Do Matchbox Have Diecast Chassis: Detailed Analysis

Matchbox cars have changed a lot over time. Their construction and materials have shaped their design and appeal. Let’s explore Matchbox chassis and compare them with other brands.

We’ll look at how materials affect durability and value. This analysis will help you understand Matchbox cars better.

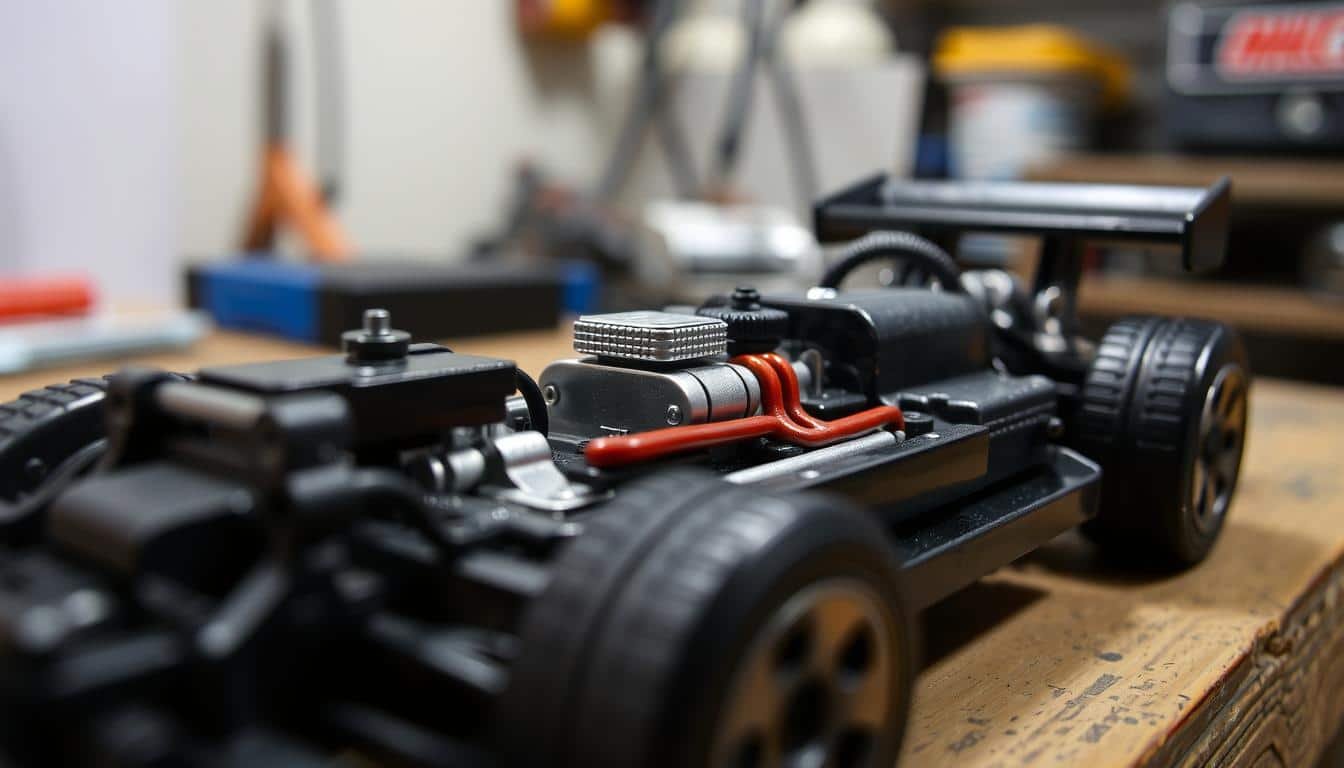

Different Types of Chassis Materials Used

Matchbox cars use various materials for their chassis. The main ones are diecast metal and plastic. Each material has its own impact on the car’s quality.

Diecast chassis feel premium and offer more stability. Plastic chassis are cost-effective and allow for flexible designs.

Comparison with Other Die-cast Manufacturers

Matchbox cars differ from other brands in size and detail. Let’s look at how the Cord model varies across brands:

| Manufacturer | Length | Width | Height | Notable Features |

|---|---|---|---|---|

| Auburn Rubber Company | 6 1/8″ | 2 3/16″ | 1 12/16″ | Thick rubber construction, durable design |

| Matchbox | 4 1/2″ | 1 3/4″ | 1 1/2″ | Detailed interior, metal chassis |

| Hot Wheels | 3 1/2″ | 1 3/16″ | 1″ | Plated bumpers, integrated undercarriage |

Impact of Materials on Durability and Value

The chassis material affects a Matchbox car’s durability and value. Diecast metal chassis last longer but may need more complex repairs.

Plastic chassis are easier to fix but less durable. Collectors often prefer metal chassis for their authentic feel and weight.

Regional Manufacturing Variations

Manufacturing locations like China and Macau can influence Matchbox car production. These regional differences may result in subtle changes in quality and design.

Collectors should consider these variations when evaluating Matchbox cars. It adds another layer of interest to collecting these miniature vehicles.

Conclusion

Matchbox collecting reveals the fascinating evolution of toy car design. Early models used mainly diecast metal chassis. Modern versions now combine metal and plastic. The 1967 K-17-A-1 Low Loader and Bulldozer exemplifies this progress in miniature vehicles.

Diecast model quality varies across different eras and models. The 1962 K-8-A Prime Mover and Transporter is considered one of Lesney’s finest toys. It sold at auction for $152.50 USD. A 1960s K-3-A Caterpillar Bulldozer fetched $24.79 AUD, showing the range in collector’s value.

Model car scales typically range from 1:63 to 1:24, with some exceptions. This size variety adds to the hobby’s appeal. Collectors appreciate both vintage and modern pieces.

The Moko small version charms with its vintage appeal. The 1980 K-8-D Animal Transporter Mercedes showcases more recent design. Each model tells a unique story of toy car evolution. Exploring this hobby deepens appreciation for miniature craftsmanship and history.

FAQ

Do all Matchbox cars have diecast chassis?

How has the construction of Matchbox cars evolved over time?

What factors influence the choice of chassis materials in Matchbox cars?

How does the use of different chassis materials affect the value of Matchbox cars?

Are there regional differences in Matchbox car construction?

How do Matchbox cars compare to other die-cast manufacturers in terms of chassis construction?

What impact does the chassis material have on a Matchbox car’s performance and durability?

Source Links

- Matchbox Motorway Layout – https://www.hobbytalk.com/threads/matchbox-motorway-layout.311769/

- A Beginners Guide to Spotting Repainted or Restored Cars – https://www.planetdiecast.com/erik/index2.php?&option=com_content&task=view&id=86371&pop=1&page=0

- Matchbox (brand) – https://en.wikipedia.org/wiki/Matchbox_(brand)

- How Are Toy Cars Made: From Concept To Creation – https://www.tinytown.in/blogs/news/how-are-toy-cars-made?srsltid=AfmBOoqyXJoLnrJCBoWGeUBrwTc5GP1qZ8fkr28vyEWjyURtDIUnzpOL

- How Do They Compare with Today’s Toys? – https://www.planetdiecast.com/index2.php?&option=com_content&task=view&id=82158&pop=1&page=0&Itemid=890

- The Fine Art Of Restoring Matchbox Cars – https://hackaday.com/2019/03/10/the-fine-art-of-restoring-matchbox-cars/

- Gunner Jim’s Lesney Matchbox Kings-Size and Super-Kings including Universal and Tyco. – https://www.planetdiecast.com/index.php?option=com_kunena&func=view&catid=124&id=60851&limit=15&limitstart=180&Itemid=18

- Model car stores – why have they always shunned realistic R/C? – https://www.tamiyaclub.com/forum/index.php?/topic/27522-model-car-stores-why-have-they-always-shunned-realistic-rc/

Interesting read! But, arent diecast metal chassis more durable than plastic? Lets discuss the longevity factor more.

I cant believe they didnt mention the nostalgic charm of the old metal Matchbox cars! Isnt it a crucial part of the evolution story?

The metal-plastic debate is endless! Why dont we push for biodegradable materials in Matchbox car designs? Sustainability, anyone?

Biodegradable? Great idea, until your prized Matchbox collection decomposes on your shelf!

Isnt it strange that despite technological advancements, were still debating metal vs plastic in Matchbox designs? Just musing.

Interesting read, but arent diecast chassis more durable and authentic? Why would Matchbox shift to plastic components? Is it cost-related?

Cost-cutting, obviously! Authenticity is sacrificed for profit. Welcome to capitalism, mate!